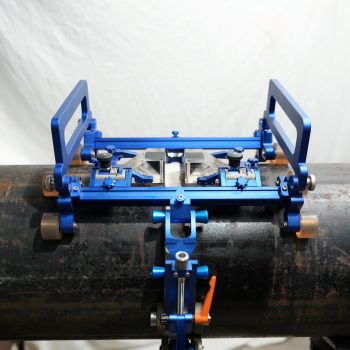

MOB Scanner appears to be a versatile and user-friendly tool for weld inspections, offering a range of features to ensure efficiency and accuracy in the scanning process.

KEY FEATURES

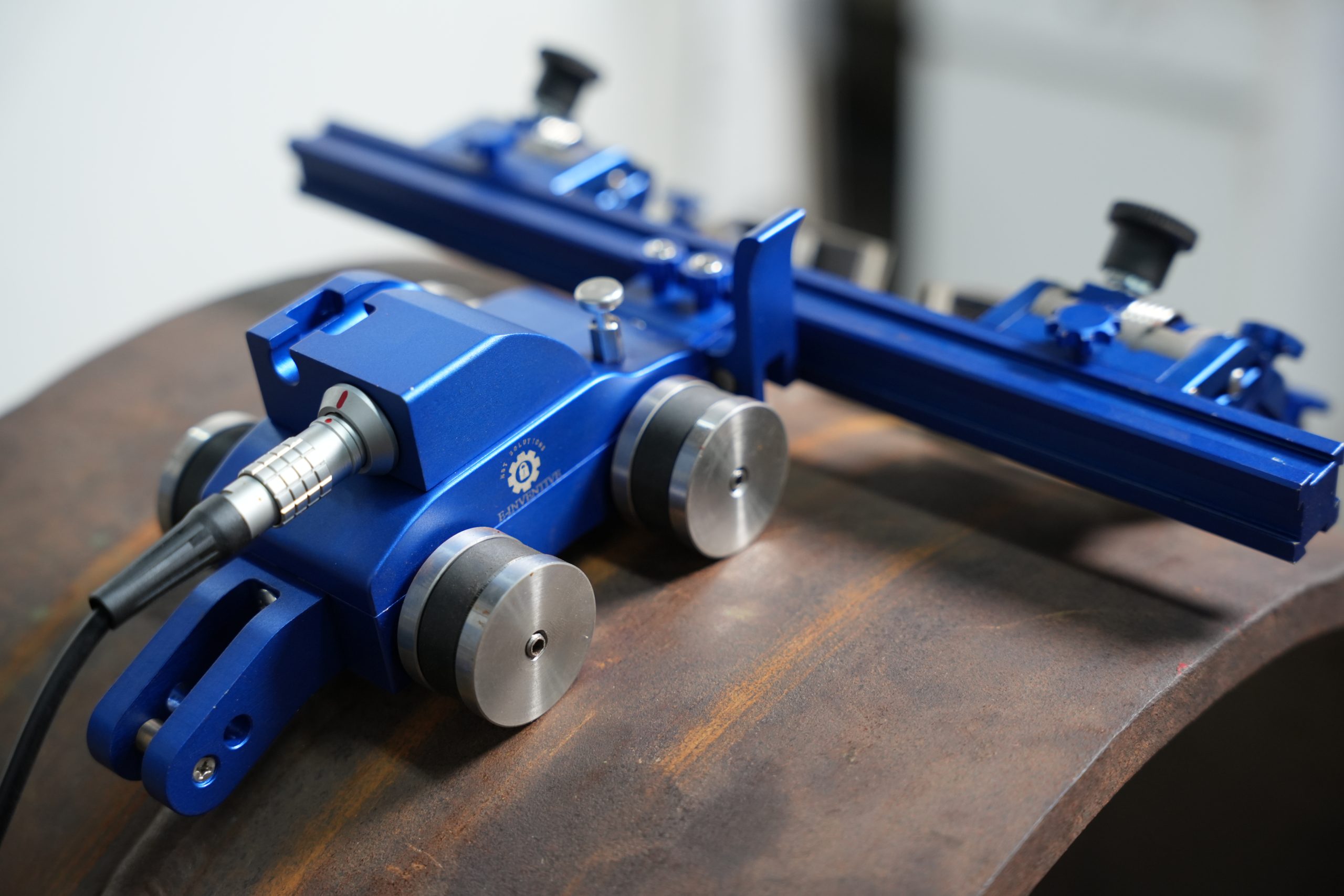

- Precision Encoding: The MOB incorporates a precise encoding system for accurate and reliable scanning of welds. This is essential for obtaining high-quality inspection data.

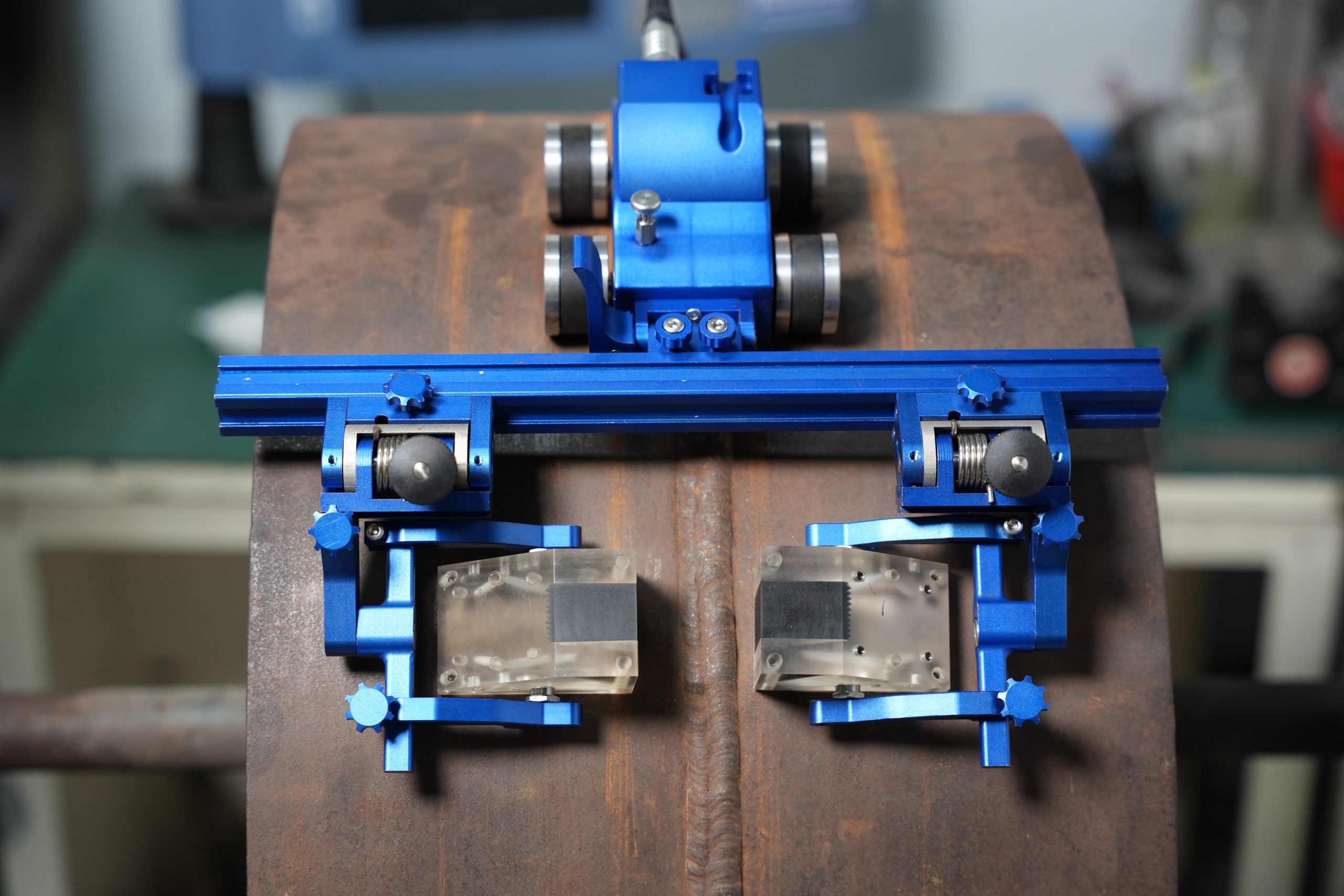

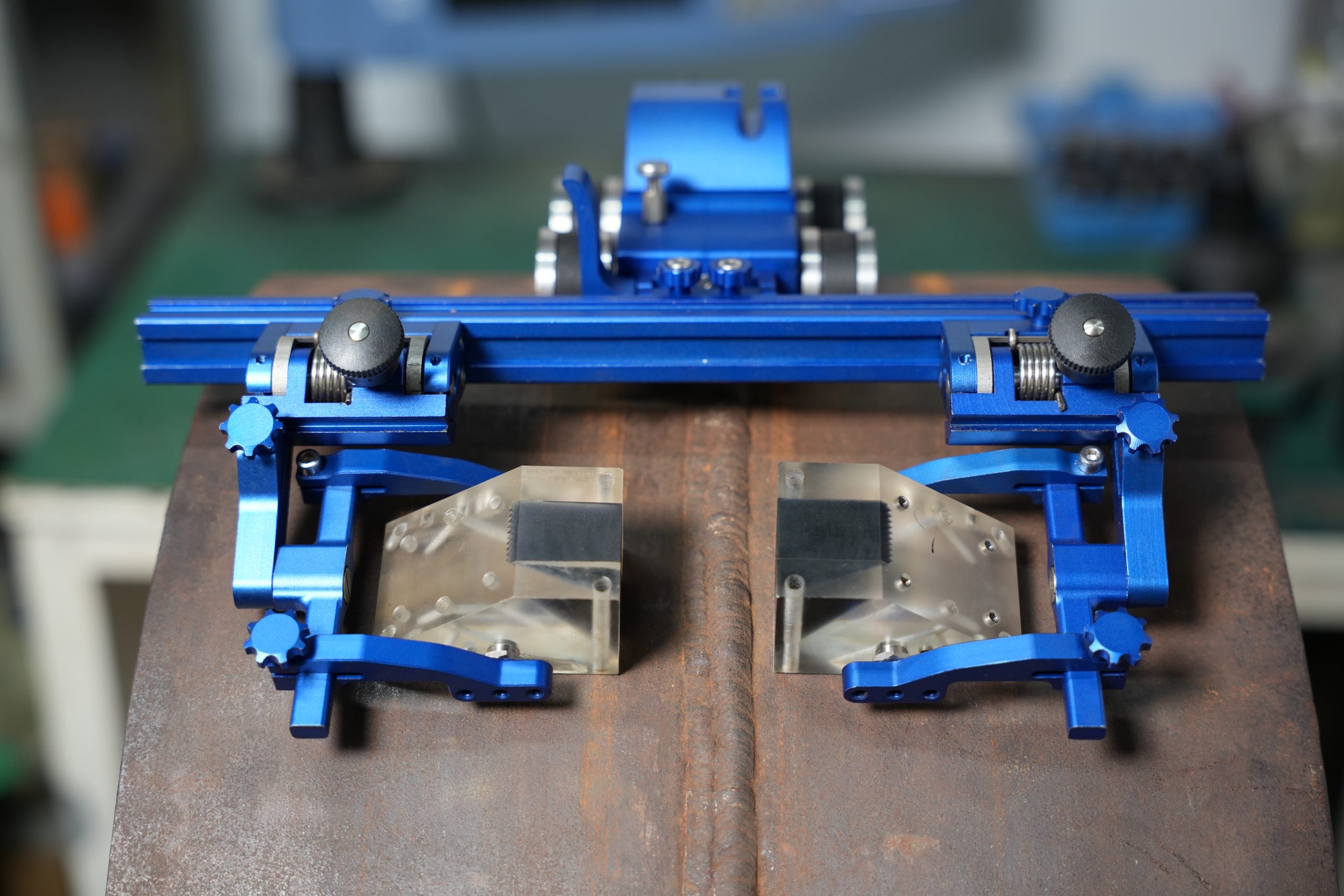

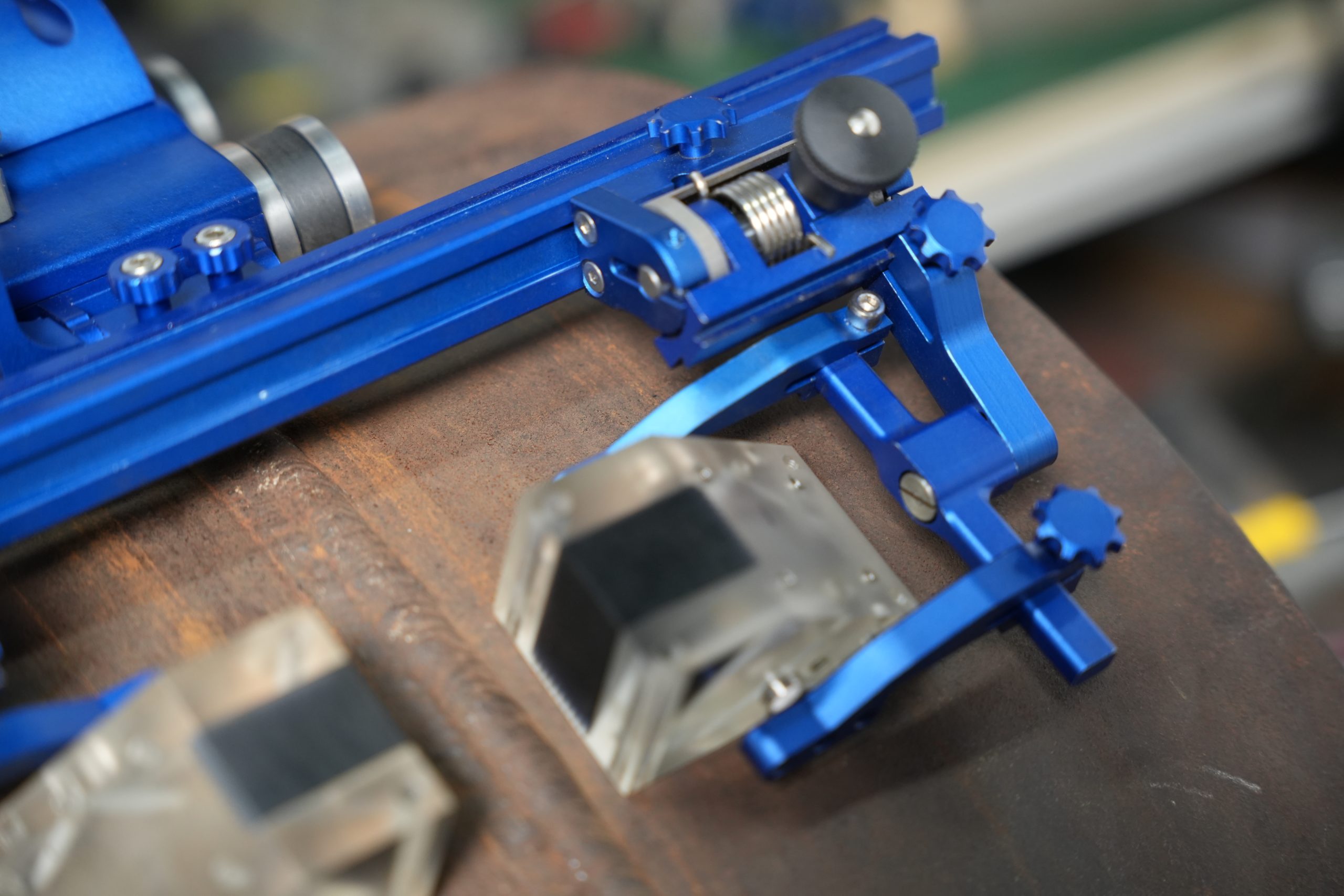

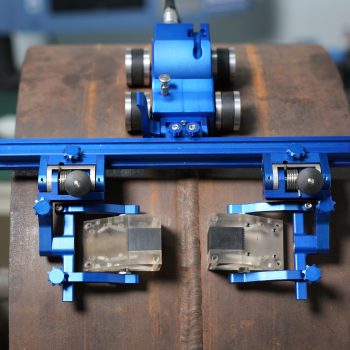

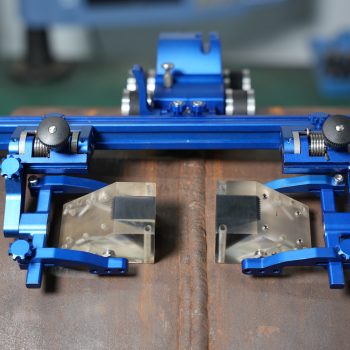

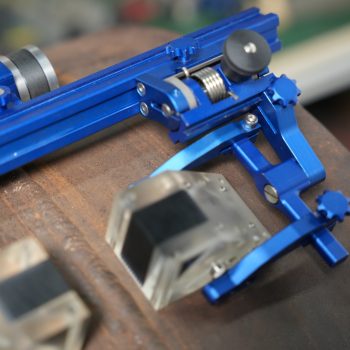

Uncomplicated Probe Holding: The probe holding mechanism is designed to be straightforward, ensuring that users can easily secure and use the probes during inspections. This simplicity contributes to a user-friendly experience. - Compact Scanning Experience: The overall design of the MOB emphasizes compactness, making it easy to handle and maneuver in tight spaces. This is particularly useful in welding environments where accessibility might be a challenge.

- Quick Setup and Ease of Use: The scanner is designed to facilitate quick setup and be user-friendly. This can save time during inspections and reduce the learning curve for operators.

- Brake for Stability: The inclusion of a brake suggests that the scanner can be securely held in place during setup.

Modular Design: The scanner’s modular design allows for the configuration of two probes in various ways. This flexibility is advantageous, as it enables the use of different types of probes or a combination of techniques like phased array and time-of-flight diffraction (TOFD).

Built-in Encoder and Magnetic Wheels: The built-in encoder helps with precise positioning and movement control during scanning. The magnetic wheels suggest that the scanner is specifically designed for use on ferrous surfaces, providing adherence for stability.

Made in Vietnam

2 year warranty

Pipe Range, Circumferential: OD 2inches to flat

Pipe Range, Longitudinal: OD 10 inches to flat.

Pipe Range, Circumferential Inner Diameter: 10 inches to flat

Magnetic Encoder (included): 1

Probe Holding Capacity: 2 Phased array probes

Umbilical Length: 5 m (16.4 ft)

Inspection Surface: Ferrous